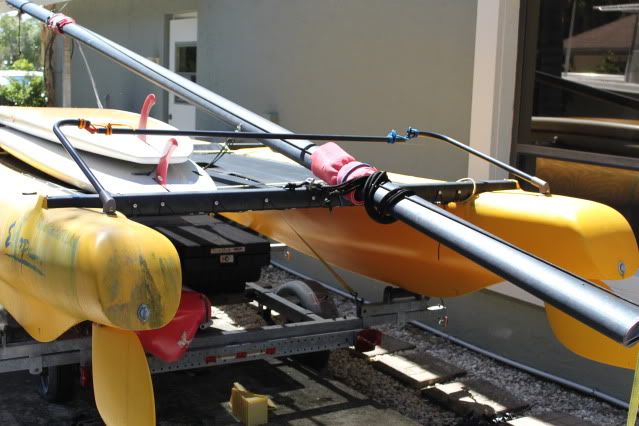

I have a 2001 Playcat (essentially the same boat as the Playcat now manufactured by Nacra). But I have a problem with the tiller:

The tiller bar connects to the risers (forgive me if my terminology is off) via two small rubber "bungies," for the lack of a better description. The old ones rotted and broke and a new pair that I managed to get from Nacra (after many, many phone calls) sheared immediately upon installation (I think their mounting holes were slightly different from the originals and this created torque). I plan to order two pairs of new ones and try another install (perhaps redrilling holes in the correct place) - should that not work, I plan to take the parts and the remaining new pair to a metal works near here and have them fabricate two small lengths of plastic-covered aircraft cable with eyes on either end to install in place of the bungies (which are held in place with a single cotter pin, so switching to cable should not be an issue - I have currently repaired it with regular bungies but they stretch to easily and it looks really jimmy-rigged - well, it is

The other issue I am dealing with is that one of the riser is significantly lower (lesser angle) than the other. There is play in both risers where they attach to the rudders, but the starboard one has more play and thus the lesser angle. I have thought about trying to find a large enough washer to install under it. If I could get ahold of Nacra (they want me to talk to the local dealer who has never seen a Playcat) and talk it through with them, I could find out what to do (with this issue and the "bungie" problem). Unfortunately, they haven't called me back.

Has anyone else had these issues and how did you address them? Or, if you are familiar with the boat do you have any thoughts? Do you see any flaws with either tiller repair option, and do you have a preference?

Thank you!

James