I disassembled the bow foil of my N5.5 with the expectation of cleaning the interface and riveting again. But the aluminum was way more corroded than expected...

https://www.thebeachcats.…ictures?g2_itemId=134137

Anybody has been there? Any advice will be greatly appreciated. Thanks!

Corroded bow foil

- Rank: Mate

- Registered: Aug 18, 2003

- Last visit: Jul 22, 2025

- Posts: 885

- Rank: Mate

- Registered: Aug 18, 2003

- Last visit: Jul 22, 2025

- Posts: 885

My preliminary thoughts:

- The surface is corroded unevenly, it looks ugly but most of the holes seem to still have some strength.

- The load is taken mostly by the cable so I'm not too concerned that the rivets will come off.

- If possible I would recover the surface with epoxy and fiber. I don't expect that it adds significant strength but it is important to have a smooth and even surface.

- I will rivet most of the holes again but for a couple of them, or additional ones, I will put bolts through the foil with washer and nut on the other side, making sure not to press too much.

- I would add a sacrifice anode to avoid further corrosion, I understand that zinc will protect aluminum, right?

Edited by Andinista on Dec 22, 2020 - 09:39 AM.

- The surface is corroded unevenly, it looks ugly but most of the holes seem to still have some strength.

- The load is taken mostly by the cable so I'm not too concerned that the rivets will come off.

- If possible I would recover the surface with epoxy and fiber. I don't expect that it adds significant strength but it is important to have a smooth and even surface.

- I will rivet most of the holes again but for a couple of them, or additional ones, I will put bolts through the foil with washer and nut on the other side, making sure not to press too much.

- I would add a sacrifice anode to avoid further corrosion, I understand that zinc will protect aluminum, right?

Edited by Andinista on Dec 22, 2020 - 09:39 AM.

- Rank: Lubber

- Registered: Jun 19, 2002

- Last visit: Oct 01, 2023

- Posts: 15

The anode won't help unless the corroded parts are submerged all the time. What you see is crevice corrosion, which is usually not helped by anodes even if the parts are submerged.

--

Chuck Miles

1978 Hobie 16

1991 Hunter 23.5

TsaLaGi Yacht Club, Jackson Bay Marina

Fort Gibson Lake, OK

--

--

Chuck Miles

1978 Hobie 16

1991 Hunter 23.5

TsaLaGi Yacht Club, Jackson Bay Marina

Fort Gibson Lake, OK

--

- Rank: Mate

- Registered: Jul 29, 2015

- Last visit: Aug 28, 2025

- Posts: 612

I assume we are looking at 30 years of corrosion here, and periodic disassembly or use of a corrosion inhibitor coating may have helped. That is galvanic corrosion between the aluminum and stainless, so whether it occurred submerged or in a crevice is immaterial. Your proposal to use glass fiber reinforced epoxy amounts to the equivalent of a "glass reinforced epoxy (GRE) gasket" and is a common solution for galvanic corrosion in pipe flanges. If you can use a cut-to-fit GRE gasket or laminate your own, and fit it between the aluminum and stainless part, then combine that with a coating of CRC 06026 Heavy Duty Corrosion Inhibitor, especially in the riveting holes, I think you will have a good long-lasting solution. It may not be maintenance free.

Considering what you found on the foil, it would be a good idea to check the rest of the connectors on the crossbars and mast.

Edited by tominpa on Dec 22, 2020 - 01:35 PM.

--

Tom

NACRA 5.7 (1984 Sail 181)

Pennsylvania

--

Considering what you found on the foil, it would be a good idea to check the rest of the connectors on the crossbars and mast.

Edited by tominpa on Dec 22, 2020 - 01:35 PM.

--

Tom

NACRA 5.7 (1984 Sail 181)

Pennsylvania

--

- Rank: Mate

- Registered: Oct 07, 2020

- Last visit: Feb 29, 2024

- Posts: 359

Let me start with a disclaimer - all of my aluminum corrosion experience is with aircraft. That includes restoring a 1946 Cessna 140 (lots of corrosion experience there!), plus building airplanes for fun and working at a helicopter company. So if this is not applicable you can dismiss it and my feelings won't be hurt.

The best option would be to replace that part. I realize that can be a challenge, both financially and even to find the parts.

Assuming that was not an option, I'd at least patch the area. I'd have a patch that was bigger than the bad spot, maybe 2X the overall area. The material should be the same type and thickness of the original, which I assume is 6061. You can probably find 6061 at your local metal supply area. Here we have Metal Supermarkets and they are pretty awesome. I did discover that if I call the local office directly the cost is about half as compared to the internet price. Otherwise you could mail order from an aircraft supply company. I would not buy anything from Lowe's Depot.

https://www.aircraftspruc…ges/alumsheet_6061t6.php

The easiest thing would be an external patch. Not sure if that would give you issues with the rigging length. If you cut out the bad area you might be able to put the doubler inside the tube, but that would be a lot harder. If it was my boat I was rescuing I'd go external.

With 6061 you have the option to weld. It may be easier to use Cherry Max rivets. The 1/8" ones, and even the 5/32" ones can be set with a normal hand rivet gun. Note the proper hole size for rivets is a #30.

https://www.aircraftspruc…g/hapages/cherrymax2.php

For corrosion proofing, I'd use an Alodine conversion coating like this. It forms a chemical conversion coating which protects against corrosion, and also makes for great paint adhesion.

https://www.aircraftspruc…e1001.php?clickkey=11999

Having paint in between those parts would be awesome. Some sort of epoxy primer would be the best, or whatever is favored in the boat world. For this area I think anything is better than nothing.

https://www.aircraftspruc…rwhite.php?clickkey=5223

If you want to read more about aircraft aluminum corrosion and repair stuff, AC43.13 is the FAA guide. Page 4-11 for repairs and page 6-25 for corrosion stuff.

https://www.faa.gov/docum…r/AC_43.13-1B_w-chg1.pdf

Good luck!

--

Bryan in Poplar Grove, IL

Supercat 17, unknown year. Future project

Hobie 16, 1977 - died a spectacular death https://youtu.be/Y7O22bp2MVA

Hobie 16, 1978 - current boat

--

The best option would be to replace that part. I realize that can be a challenge, both financially and even to find the parts.

Assuming that was not an option, I'd at least patch the area. I'd have a patch that was bigger than the bad spot, maybe 2X the overall area. The material should be the same type and thickness of the original, which I assume is 6061. You can probably find 6061 at your local metal supply area. Here we have Metal Supermarkets and they are pretty awesome. I did discover that if I call the local office directly the cost is about half as compared to the internet price. Otherwise you could mail order from an aircraft supply company. I would not buy anything from Lowe's Depot.

https://www.aircraftspruc…ges/alumsheet_6061t6.php

The easiest thing would be an external patch. Not sure if that would give you issues with the rigging length. If you cut out the bad area you might be able to put the doubler inside the tube, but that would be a lot harder. If it was my boat I was rescuing I'd go external.

With 6061 you have the option to weld. It may be easier to use Cherry Max rivets. The 1/8" ones, and even the 5/32" ones can be set with a normal hand rivet gun. Note the proper hole size for rivets is a #30.

https://www.aircraftspruc…g/hapages/cherrymax2.php

For corrosion proofing, I'd use an Alodine conversion coating like this. It forms a chemical conversion coating which protects against corrosion, and also makes for great paint adhesion.

https://www.aircraftspruc…e1001.php?clickkey=11999

Having paint in between those parts would be awesome. Some sort of epoxy primer would be the best, or whatever is favored in the boat world. For this area I think anything is better than nothing.

https://www.aircraftspruc…rwhite.php?clickkey=5223

If you want to read more about aircraft aluminum corrosion and repair stuff, AC43.13 is the FAA guide. Page 4-11 for repairs and page 6-25 for corrosion stuff.

https://www.faa.gov/docum…r/AC_43.13-1B_w-chg1.pdf

Good luck!

--

Bryan in Poplar Grove, IL

Supercat 17, unknown year. Future project

Hobie 16, 1977 - died a spectacular death https://youtu.be/Y7O22bp2MVA

Hobie 16, 1978 - current boat

--

- Rank: Mate

- Registered: Oct 07, 2020

- Last visit: Feb 29, 2024

- Posts: 359

The other thought I had was to re-make the steel part, and make the plate section 2X bigger in area. Looks like an easy part to make. That corroded aluminum doesn't have any strength left.

--

Bryan in Poplar Grove, IL

Supercat 17, unknown year. Future project

Hobie 16, 1977 - died a spectacular death https://youtu.be/Y7O22bp2MVA

Hobie 16, 1978 - current boat

--

--

Bryan in Poplar Grove, IL

Supercat 17, unknown year. Future project

Hobie 16, 1977 - died a spectacular death https://youtu.be/Y7O22bp2MVA

Hobie 16, 1978 - current boat

--

- Rank: Mate

- Registered: Aug 18, 2003

- Last visit: Jul 22, 2025

- Posts: 885

- Rank: Mate

- Registered: Jul 29, 2015

- Last visit: Aug 28, 2025

- Posts: 612

- Rank: Mate

- Registered: Aug 18, 2003

- Last visit: Jul 22, 2025

- Posts: 885

- Rank: Mate

- Registered: Oct 24, 2006

- Last visit: Aug 01, 2025

- Posts: 162

I'd keep it simple; use a corrosion inhibiter to keep it from degrading further. Possibly use a thin layer of material (UMHW "slick tape"?) to act as an isolator and reattach with rivets (also using inhibitor in the holes).

Yes and no, to match the current lateral load, you would need to determine and match the angle of the short wires that attach the bridle to the bows. More modern boats use a conventional split forestay, but add a solid extension below the split that attaches to the spinnaker pole. Having owned a 6.0, I suspect that the angle of the wires would make the split in the forestay much higher than a conventional modern forestay.

Yes and no, to match the current lateral load, you would need to determine and match the angle of the short wires that attach the bridle to the bows. More modern boats use a conventional split forestay, but add a solid extension below the split that attaches to the spinnaker pole. Having owned a 6.0, I suspect that the angle of the wires would make the split in the forestay much higher than a conventional modern forestay.

- Rank: Mate

- Registered: Aug 18, 2003

- Last visit: Jul 22, 2025

- Posts: 885

- Rank: Mate

- Registered: Jul 29, 2015

- Last visit: Aug 28, 2025

- Posts: 612

Andinista, I mentioned the CRC 06026 Heavy Duty Corrosion Inhibitor earlier. It is intended for marine use like this. If you are going to turn the foil to a new surface, then on top of the inhibitor, add a strip of Marine Butyl Rubber Tape https://shop.marinehowto.com/products/bed-it-tape This is the same material we use to bed and waterproof fixtures on monohulls. It will totally exclude any water from under the fixture. It is extruded very thin and is compressible. If you run it around the edge of the stainless part and where rivets penetrate, and press it into place it will stay pliable and keep out water for many years. Without the water, and placed on a corrosion barrier, this will not happen again.

Edited by tominpa on Dec 22, 2020 - 06:25 PM.

--

Tom

NACRA 5.7 (1984 Sail 181)

Pennsylvania

--

Edited by tominpa on Dec 22, 2020 - 06:25 PM.

--

Tom

NACRA 5.7 (1984 Sail 181)

Pennsylvania

--

- Rank: Mate

- Registered: Aug 18, 2003

- Last visit: Jul 22, 2025

- Posts: 885

- Rank: Mate

- Registered: Aug 18, 2003

- Last visit: Jul 22, 2025

- Posts: 885

- Rank: Mate

- Registered: Jul 29, 2015

- Last visit: Aug 28, 2025

- Posts: 612

- Rank: Mate

- Registered: Aug 18, 2003

- Last visit: Jul 22, 2025

- Posts: 885

- Rank: Mate

- Registered: Aug 13, 2017

- Last visit: Jan 26, 2025

- Posts: 282

Hi Andinista,

Sweden

Remember we had a discussion a few years back about bridle angles? It gave me a lot!

After that I rebuilt and widened my 5.5 to get rid of the clumsy, heavy and also heavily corroded bow foil. Also replaced the rig with a F18 complete with spin. The arrangement with the spinpole was totally overworked with the striker thing under the pole. Will go to the normal style with lines to each bow next year. Note my compression tube is quite long as the F18 jib sits lower than the 5.5.

Took a random image from the internet to show how I would do today, w and w/o spinnaker, if I hadn´t widened my 5.5. The "real" bridle lines are 4mm DM20, the others 3mm DM20 and the compression tube is a flattened 16mm stainless. This involves shortening the forestay and a simple modification of the jib zipper.

Will also save a quite a few kg of boatweight as this arrangement is just a few hundred grams.

Edited by revintage on Dec 23, 2020 - 06:54 AM.

--

Brgds

Lars

Frankentri 5.8/5.5/Inter20

Aerow trimaran foiler

https://www.facebook.com/groups/1192604934176635

--

Sweden

Remember we had a discussion a few years back about bridle angles? It gave me a lot!

After that I rebuilt and widened my 5.5 to get rid of the clumsy, heavy and also heavily corroded bow foil. Also replaced the rig with a F18 complete with spin. The arrangement with the spinpole was totally overworked with the striker thing under the pole. Will go to the normal style with lines to each bow next year. Note my compression tube is quite long as the F18 jib sits lower than the 5.5.

Took a random image from the internet to show how I would do today, w and w/o spinnaker, if I hadn´t widened my 5.5. The "real" bridle lines are 4mm DM20, the others 3mm DM20 and the compression tube is a flattened 16mm stainless. This involves shortening the forestay and a simple modification of the jib zipper.

Will also save a quite a few kg of boatweight as this arrangement is just a few hundred grams.

Edited by revintage on Dec 23, 2020 - 06:54 AM.

--

Brgds

Lars

Frankentri 5.8/5.5/Inter20

Aerow trimaran foiler

https://www.facebook.com/groups/1192604934176635

--

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

- Rank: Mate

- Registered: Oct 07, 2020

- Last visit: Feb 29, 2024

- Posts: 359

I was assuming aluminum oxide. It's pretty ugly looking!

Clever idea to turn the foil around. Will you patch the other side?

--

Bryan in Poplar Grove, IL

Supercat 17, unknown year. Future project

Hobie 16, 1977 - died a spectacular death https://youtu.be/Y7O22bp2MVA

Hobie 16, 1978 - current boat

--

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

- Rank: Mate

- Registered: Jul 29, 2015

- Last visit: Aug 28, 2025

- Posts: 612

MN3, I think you are right. It is most likely a polyester adhesive bedding material like 3M-5200 pr 3M-4200 that has failed. The color is right, and this is how it fails in hardware that has been in use a long time and has some movement https://www.3m.com/3M/en_…002385+3293241623&rt=rud

We have moved away from this material because it does dry out and fail and started using the butyl rubber I showed in a previous post. While 3M-5200 is a strong adhesive as well as sealant, the adhesive is just not needed where fasteners like rivets, bolts and screws are providing a mechanical attachment. On monohulls it is a pain in the ass to remove, and its failure results in soft decks. The butyl rubber never dries or fails and moves in shear, tension and compression without losing its seal.

Edited by tominpa on Dec 23, 2020 - 08:07 PM.

--

Tom

NACRA 5.7 (1984 Sail 181)

Pennsylvania

--

We have moved away from this material because it does dry out and fail and started using the butyl rubber I showed in a previous post. While 3M-5200 is a strong adhesive as well as sealant, the adhesive is just not needed where fasteners like rivets, bolts and screws are providing a mechanical attachment. On monohulls it is a pain in the ass to remove, and its failure results in soft decks. The butyl rubber never dries or fails and moves in shear, tension and compression without losing its seal.

Edited by tominpa on Dec 23, 2020 - 08:07 PM.

--

Tom

NACRA 5.7 (1984 Sail 181)

Pennsylvania

--

- Rank: Mate

- Registered: Aug 18, 2003

- Last visit: Jul 22, 2025

- Posts: 885

Will check the suggestions about corrosion protection now

YES!!!!

what is this you are holding ? some anti fouling or silicone or something? can't be aluminum oxide is it? (looks thicker than the foil metal to me)

I was assuming aluminum oxide. It's pretty ugly looking!

Clever idea to turn the foil around. Will you patch the other side?

Yes, it is the aluminum oxide!! It grows thicker than in its previous state.. it’s taken from all the crap visible in other pictures.

The hand would be my daughter’s, so adjust scale a little bit :)

Yes, I will probably patch the corroded part, not sure how necessary it is, but for peace of mind

- Rank: Mate

- Registered: Aug 18, 2003

- Last visit: Jul 22, 2025

- Posts: 885

Before disassembling it didn’t look as bad, the worse was closer to the center that in the edges.But I had not realized that the white stuff was the aluminum itself, I thought that the rivets were coming loose and that the white stuff was some sort of buildup coming from outside.

Edited by Andinista on Dec 23, 2020 - 10:19 PM.

Edited by Andinista on Dec 23, 2020 - 10:19 PM.

- Rank: Mate

- Registered: Aug 18, 2003

- Last visit: Jul 22, 2025

- Posts: 885

- Rank: Mate

- Registered: Aug 18, 2003

- Last visit: Jul 22, 2025

- Posts: 885

- Rank: Mate

- Registered: Jul 29, 2015

- Last visit: Aug 28, 2025

- Posts: 612

Not sure. I would expect if it was used as a sealant or adhesive, the thickness could be uneven. Aluminum oxide corrosion can expand to fill any space, and in the oxide form is much larger than the metal it came from. It is soft, flaky and usually retains moisture. I guess, photos have their limits, and from here in Pennsylvania, I just can't tell you. Is the material "friable"? Does it fall apart easily when rubbed between your fingers? I can't tell if the material is a chalky, friable metal or a chunk of plastic caulk.

--

Tom

NACRA 5.7 (1984 Sail 181)

Pennsylvania

--

--

Tom

NACRA 5.7 (1984 Sail 181)

Pennsylvania

--

- Rank: Mate

- Registered: Aug 18, 2003

- Last visit: Jul 22, 2025

- Posts: 885

- Rank: Mate

- Registered: Nov 22, 2012

- Last visit: Jan 27, 2025

- Posts: 419

This is very common with stainless and aluminum. I’ve run across it a lot. Maybe you have, but wire brush the corrosion to see how bad it really is. Ultimately, I would suggest replacing the foil. I have built a foil for my boat out of a H-16 boom. My second option would be to have the base of the full striker built larger. I would stay away from flipping the foil over. If the corroded area is compromised, you’ll add a weak spot to a pretty high load area. I think the foil will fold. Which ever you do, make sure you use a corrosion inhibitor paste in between all dissimilar metals.

--

Scott

Prindle Fleet 2

TCDYC

Prindle 18-2 Mod "FrankenKitty"

Tornado Classic "Fast Furniture"

Prindle 19 "Mr. Wiggly"

Nacra 5.8 "De ja vu"

Nacra 5.0

Nacra 5.8

Tornadoes (Reg White)

--

--

Scott

Prindle Fleet 2

TCDYC

Prindle 18-2 Mod "FrankenKitty"

Tornado Classic "Fast Furniture"

Prindle 19 "Mr. Wiggly"

Nacra 5.8 "De ja vu"

Nacra 5.0

Nacra 5.8

Tornadoes (Reg White)

--

- Rank: Mate

- Registered: Aug 18, 2003

- Last visit: Jul 22, 2025

- Posts: 885

I was looking for CRC 06026 and its cheap but shipping to chile adds up consierably, it's probably considered hazardous or something. Not to kill me but I'd rather go the double bridles way, considering that I have some wires and would just need to swage them.

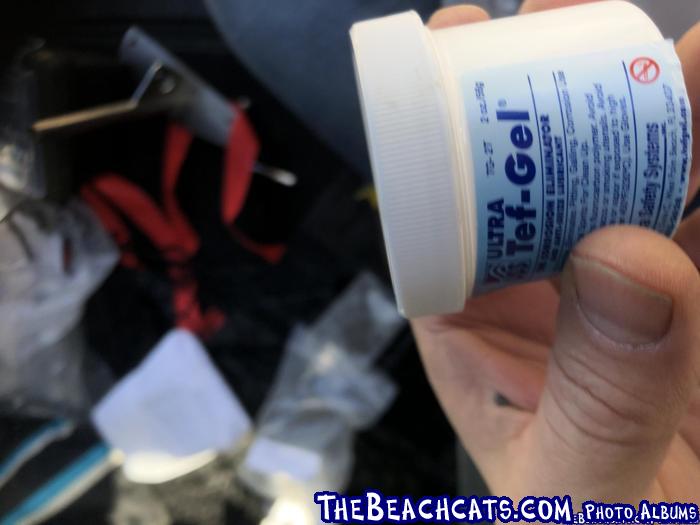

But I do have a small pot of TEF GEL that should be enough. According to the video below it's the right thing, what do you think?

How bad would it be to skip the butyl tape and just apply the TEF GEL? I'm not planing to sail this boat other 20 years anyway... And to sell it I'd probably swage those wires anyway.

https://corrosionandmarine.com/

Edited by Andinista on Dec 29, 2020 - 10:05 AM.

But I do have a small pot of TEF GEL that should be enough. According to the video below it's the right thing, what do you think?

How bad would it be to skip the butyl tape and just apply the TEF GEL? I'm not planing to sail this boat other 20 years anyway... And to sell it I'd probably swage those wires anyway.

https://corrosionandmarine.com/

Edited by Andinista on Dec 29, 2020 - 10:05 AM.

- Rank: Mate

- Registered: Jul 29, 2015

- Last visit: Aug 28, 2025

- Posts: 612

I have never used it in marine, but plumbing uses TEF all the time, and it works well. It's worth remembering it took a long time for the corrosion to occur the first time, and any solution you apply will likely be effective in preventing it or slowing it down now.

--

Tom

NACRA 5.7 (1984 Sail 181)

Pennsylvania

--

--

Tom

NACRA 5.7 (1984 Sail 181)

Pennsylvania

--

- Rank: Mate

- Registered: Aug 18, 2003

- Last visit: Jul 22, 2025

- Posts: 885

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

But I do have a small pot of TEF GEL that should be enough. According to the video below it's the right thing, what do you think?

How bad would it be to skip the butyl tape and just apply the TEF GEL? I'm not planing to sail this boat other 20 years anyway... And to sell it I'd probably swage those wires anyway.

https://corrosionandmarine.com/Edited by Andinista on Dec 29, 2020 - 10:05 AM.

I have used tef gel for years

it is superb as a barrier to reduce galv. corrosion

i suggest you don't use your fingers to spread the product like the man in the video

it is nasty stuff and while not caustic - probably not a good idea to use like that. i always wear disposable gloves and use it after dry fitting everything

- Rank: Mate

- Registered: Nov 22, 2012

- Last visit: Jan 27, 2025

- Posts: 419

The last couple of times sailing, I notice my bow foil acting funky - weird bending going on. Doing some winter maintenance, I noticed the thimble for the gull striker had compressed. It is a 3/16" sailmaker thimble. I do push the boat hard, just didn't realize how hard. Tried to post a pic, but it wouldn't stick.

--

Scott

Prindle Fleet 2

TCDYC

Prindle 18-2 Mod "FrankenKitty"

Tornado Classic "Fast Furniture"

Prindle 19 "Mr. Wiggly"

Nacra 5.8 "De ja vu"

Nacra 5.0

Nacra 5.8

Tornadoes (Reg White)

--

--

Scott

Prindle Fleet 2

TCDYC

Prindle 18-2 Mod "FrankenKitty"

Tornado Classic "Fast Furniture"

Prindle 19 "Mr. Wiggly"

Nacra 5.8 "De ja vu"

Nacra 5.0

Nacra 5.8

Tornadoes (Reg White)

--

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

- Rank: Lubber

- Registered: Jun 06, 2002

- Last visit: Jan 25, 2021

- Posts: 1

Andinista,

Given your corrosion issue, as a former Nacra 5.5 owner, if you have not yet, I would suggest you inspect the front beam at the inner ends where the dolphin striker horizontal support bolts to the beam (3 bolts per side). By boat had corrosion there and I put small plates inside the beam to improve the structure where the corrosion had weakened it.

Patrick

Given your corrosion issue, as a former Nacra 5.5 owner, if you have not yet, I would suggest you inspect the front beam at the inner ends where the dolphin striker horizontal support bolts to the beam (3 bolts per side). By boat had corrosion there and I put small plates inside the beam to improve the structure where the corrosion had weakened it.

Patrick

- Rank: Mate

- Registered: Aug 18, 2003

- Last visit: Jul 22, 2025

- Posts: 885

- Rank: Mate

- Registered: Aug 18, 2003

- Last visit: Jul 22, 2025

- Posts: 885

Hi!

After quite a while I repaired my bowfoil, here are the pictures.

Conclusions:

* I seriously considered to make double bridles instead, but then realized that I like to roll the jib on the forestay (even without roller furling), so I didn't.

* I will seal the rivets and plates edges to keep water away

* I love Tef-Gel

* There is little room for the plate that I added. I had to press the foil with my foot to bend it a little bit to be able to connect again the wires at both ends

Before:

After:

After quite a while I repaired my bowfoil, here are the pictures.

Conclusions:

* I seriously considered to make double bridles instead, but then realized that I like to roll the jib on the forestay (even without roller furling), so I didn't.

* I will seal the rivets and plates edges to keep water away

* I love Tef-Gel

* There is little room for the plate that I added. I had to press the foil with my foot to bend it a little bit to be able to connect again the wires at both ends

Before:

After:

- Rank: Mate

- Registered: Nov 22, 2012

- Last visit: Jan 27, 2025

- Posts: 419

https://www.thebeachcats.…ictures?g2_itemId=134137

Anybody has been there? Any advice will be greatly appreciated. Thanks!

You did a great job on the repair. I use Tuff Gel or LanoCote for corrosion inhibitors. It's a shame that Performance didn't care to insulate these foil parts. I have seen and repaired quite a few of them.

--

Scott

Prindle Fleet 2

TCDYC

Prindle 18-2 Mod "FrankenKitty"

Tornado Classic "Fast Furniture"

Prindle 19 "Mr. Wiggly"

Nacra 5.8 "De ja vu"

Nacra 5.0

Nacra 5.8

Tornadoes (Reg White)

--