I have a small leak in my centerboard well (usual spot for leaks)

it is in a spot that is gonna be really hard to access - requiring sanding via a 4' extension and even then, it is on a curved surface that i am not sure how i can actually scuff up well

i can just about reach the hole from under that boat but it's tough - and i don't really want to sand above my head for extended periods of time

the biggest issue is post cure - the epoxy is gonna be reallllll tough to smooth and it's in a tight fitting spot on the board well= any edge is gonna skuff up and possibly damage the board when it's moved into spot

any product like a 2 part pool epoxy i can reliable stuff in there that will last for years?

looking for a better way to fix a leak in a board well

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

- Rank: Mate

- Registered: Apr 15, 2005

- Last visit: Apr 30, 2025

- Posts: 576

These are tough problems, tight spots in the back of a board well..

The best approach I've found is to mix some G/Flex 655, and place in the known leaking area with a bent acid brush attached to a dowel rod. Apply vacuum to the hull if you are really concerned, it should suck the epoxy into the area.

The other option if its a really thin hole is the same approach but with raw West Systems or other epoxy. I find the G/flex a good option in board trunks though because its a tiny bit flexible and normally the trunks themselves are super thin glass that tends to flex a bit under load.

The best approach I've found is to mix some G/Flex 655, and place in the known leaking area with a bent acid brush attached to a dowel rod. Apply vacuum to the hull if you are really concerned, it should suck the epoxy into the area.

The other option if its a really thin hole is the same approach but with raw West Systems or other epoxy. I find the G/flex a good option in board trunks though because its a tiny bit flexible and normally the trunks themselves are super thin glass that tends to flex a bit under load.

- Rank: Mate

- Registered: Apr 15, 2005

- Last visit: Apr 30, 2025

- Posts: 576

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

- Rank: Mate

- Registered: May 09, 2009

- Last visit: Aug 14, 2024

- Posts: 686

Do you have drain plugs in your hulls? I used a small shop vac on one of my H18's that had a leak in a seam

in the dagger well. Worked good to draw in the epoxy. Just had someone stick the vacuum hose over the drain

hole while I applied epoxy. Went quick and we did not maintain any vacuum after the epoxy was drawn in.

Thinking out loud you could install a vacuum gauge in a spare hatch cover to monitor how much you have in the hull.

Edited by pknapp66 on Jul 16, 2019 - 11:47 AM.

--

Pete Knapp

Schodack landing,NY

Goodall Viper,AHPC Viper,Nacra I20

--

in the dagger well. Worked good to draw in the epoxy. Just had someone stick the vacuum hose over the drain

hole while I applied epoxy. Went quick and we did not maintain any vacuum after the epoxy was drawn in.

Thinking out loud you could install a vacuum gauge in a spare hatch cover to monitor how much you have in the hull.

Edited by pknapp66 on Jul 16, 2019 - 11:47 AM.

--

Pete Knapp

Schodack landing,NY

Goodall Viper,AHPC Viper,Nacra I20

--

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

- Rank: Mate

- Registered: Mar 19, 2004

- Last visit: Sep 03, 2025

- Posts: 968

No way to internally access the hull? Getting a glass patch on the inside is going to be a much more reliable and permanent solution than using straight epoxy on the outside.

How bad is the leak? If you’re only talking a small amount, might be better off just leaving it alone and living with it (sponge out through an access port periodically if it really bothers you).

And on another note, wholy crap, 15PSI? I’ve detected leaks in boats by just blowing into the drain plug with my mouth. Surprized you did not damage the boat with that much pressure.

sm

How bad is the leak? If you’re only talking a small amount, might be better off just leaving it alone and living with it (sponge out through an access port periodically if it really bothers you).

And on another note, wholy crap, 15PSI? I’ve detected leaks in boats by just blowing into the drain plug with my mouth. Surprized you did not damage the boat with that much pressure.

sm

- Rank: Mate

- Registered: May 09, 2009

- Last visit: Aug 14, 2024

- Posts: 686

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

not without cutting an access hole on the bottom of my inner hull - that is not a good solution to me

couple gallons after 7 hours of sailing = too much for my happiness + if it gets worse ...

it wasn't 15psi of pressure in the hull - that was the setting on the compressor

i used a wet cloth around the nozzle and it certainly was not a tight fit

also 4 small holes in my deck prevent any real pressure (turning blocks for the centerboard bungee that were removed) - but noted: it doesn't take a ton of pressure to blow bubbles in soapy water

- Rank: Chief

- Registered: Apr 19, 2011

- Last visit: Feb 19, 2025

- Posts: 1462

There was a three way puncture in my Prindle centerboard well from a rock that got wedged inside. It was past my fingers up from the bottom. I laid the cat on its side, tied to the fence, so that the injury was facing up. I used paint stir sticks with sandpaper glued to them to rough up the area. Using Marine Tex, which is thick to go on and dries very hard, I applied it with another paint stir stick. A strong flashlight helped me make sure I got it as smooth as possible, then more sanding to keep it from scratching the centerboard.

My $0.02...

YMMV

Good luck!

--

Sheet In!

Bob

_/)_____/)_/)____/)____/)_____/)/)__________/)__

Prindle 18-2 #244 "Wakizashi"

Prindle 16 #3690 "Pegasus" Sold (sigh)

AZ Multihull Fleet 42 member

(Way) Past Commodore of Prindle Fleet 14

Arizona, USA

--

My $0.02...

YMMV

Good luck!

--

Sheet In!

Bob

_/)_____/)_/)____/)____/)_____/)/)__________/)__

Prindle 18-2 #244 "Wakizashi"

Prindle 16 #3690 "Pegasus" Sold (sigh)

AZ Multihull Fleet 42 member

(Way) Past Commodore of Prindle Fleet 14

Arizona, USA

--

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

thanks for all the input

I have used wax paper on repairs before . - just as the epoxy or gel-coat kicks off i add the wax paper and smooth it out with my hand (or tool) - just not sure i can access this spot like this

Bob, why did you tie your cat to the fence? afraid it might get loose? :)

I have used wax paper on repairs before . - just as the epoxy or gel-coat kicks off i add the wax paper and smooth it out with my hand (or tool) - just not sure i can access this spot like this

Bob, why did you tie your cat to the fence? afraid it might get loose? :)

- Rank: Chief

- Registered: Apr 19, 2011

- Last visit: Feb 19, 2025

- Posts: 1462

Truth be told, it has gotten away from me many times, but not so much in the back yard. I was taking no chances though!

--

Sheet In!

Bob

_/)_____/)_/)____/)____/)_____/)/)__________/)__

Prindle 18-2 #244 "Wakizashi"

Prindle 16 #3690 "Pegasus" Sold (sigh)

AZ Multihull Fleet 42 member

(Way) Past Commodore of Prindle Fleet 14

Arizona, USA

--

- Rank: Mate

- Registered: Sep 16, 2016

- Last visit: Sep 10, 2021

- Posts: 274

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

- Rank: Mate

- Registered: Jun 15, 2016

- Last visit: Apr 14, 2022

- Posts: 181

I will offer two ideas that are probably both bad... But hey, who knows. First bad idea: Stand boat with bows up (yeah, easy to do, lol), dry thoroughly, sand, clean, and allow West System 105 to flow into gap. Second bad idea: dry thoroughly, sand, clean, smear West System 610 into the back of board well, build up the back edge of the daggerboard with tape, lube the hell out of it, then slide into the well. Hope you can get the board out. If you can get it out easily, then you'll be in the clear. Very important to evenly apply the tape so it slides out later.

Edited by traphappy on Jul 16, 2019 - 04:41 PM.

Edited by traphappy on Jul 16, 2019 - 04:41 PM.

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

it's not in the "back" of the well

it is on the side (towards the inside of the boat)

looking down the well it is about 4" above the bottom lip (which has a gasket on it)

it is in a curved area of the well (i assume these curves are there for added strenght - the well walls are crazy thin like Sam mentioned above)

the curve area has a "bowl" shape to it (think of a 1/2 baseball) and it is inside the curve - that is where the real challenge is to sanding it is out of reach and in a spot that a flat item wont be able to get to

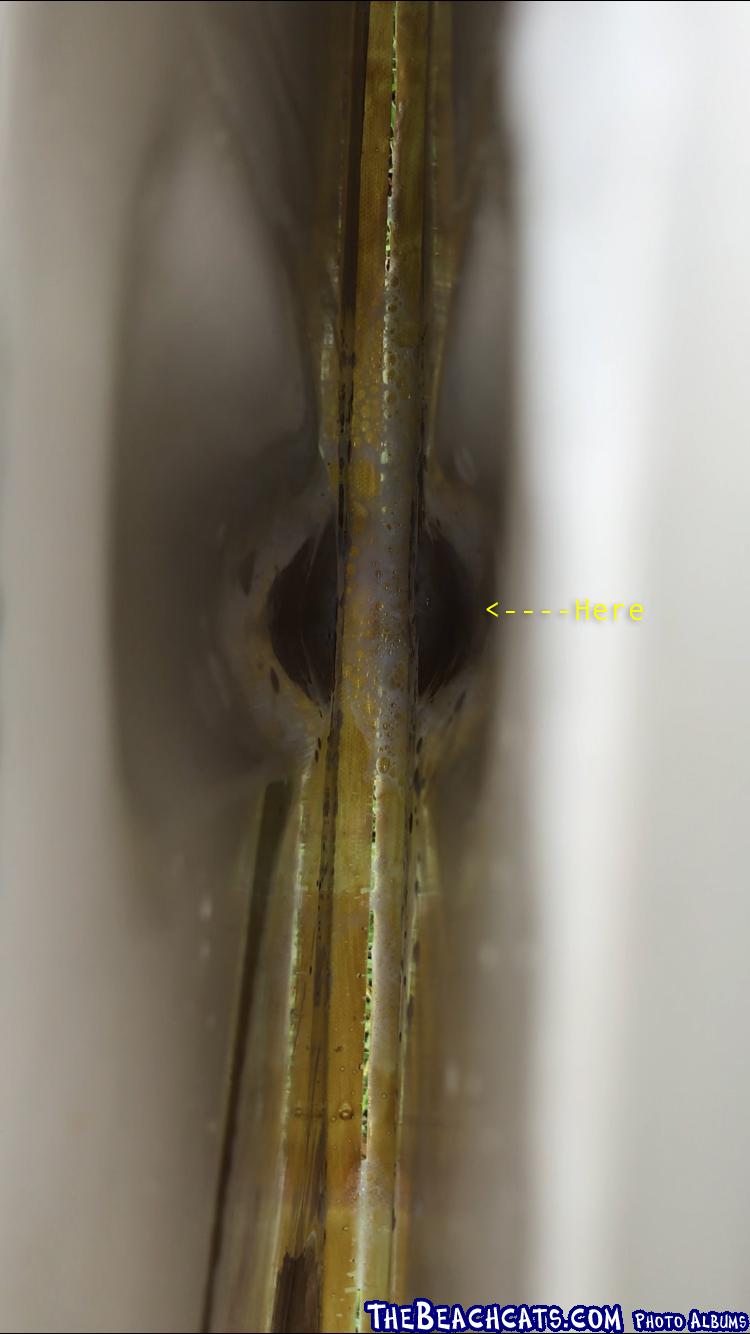

This image is looking down - the yellow strip in the middle is the gasket with a bunch of soap suds on it (this is from a phone video i shot while checking for leaks)

it is on the side (towards the inside of the boat)

looking down the well it is about 4" above the bottom lip (which has a gasket on it)

it is in a curved area of the well (i assume these curves are there for added strenght - the well walls are crazy thin like Sam mentioned above)

the curve area has a "bowl" shape to it (think of a 1/2 baseball) and it is inside the curve - that is where the real challenge is to sanding it is out of reach and in a spot that a flat item wont be able to get to

This image is looking down - the yellow strip in the middle is the gasket with a bunch of soap suds on it (this is from a phone video i shot while checking for leaks)

- Rank: Mate

- Registered: Sep 16, 2016

- Last visit: Sep 10, 2021

- Posts: 274

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

- Rank: Mate

- Registered: Jun 15, 2016

- Last visit: Apr 14, 2022

- Posts: 181

- Rank: Mate

- Registered: Apr 15, 2005

- Last visit: Apr 30, 2025

- Posts: 576

Ah yes. I've done this repair on the beach, but on an Infusion Mk. 2 which has more room to work I think than what you have there. Tip boat on its side and work from the bottom with the same technique I mentioned. I would try and get glass in there if possible, and traphappy's suggestion of a waxed up board is a good one.

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

the hole is not on the wall where it would touch the board

it is inside a recess just is inside the lip.

look at the pic again : instead of looking at the arrow at the bottom of the well (where the leak is) look at the top of the well, on the left - it's the exact same shape

i don't think a patch is the right call because the patch would be almost impossible to get in the exact right location and if it was hanging outside the recess at all - it will scratch up the board

I am tempted to use 2 part pool epoxy - it stays flexible and can last for a very long time and is a 4 minute job (just mix it and smoosh it into the hole)

But i know the right way is to flip, and add some vacuum

thanks all!

Edited by MN3 on Jul 17, 2019 - 09:56 AM.

- Rank: Lubber

- Registered: Jan 08, 2007

- Last visit: Mar 23, 2023

- Posts: 49

Andrew

What about the use of a rat tail file to sand it down? Round Rat Tail Diamond Needle Files 10-Inch Round Shape 180#

by NICELEC Industrial

5.0 out of 5 stars 1 customer review

Price: $9.36 & FREE Shipping

Not easy to break

Grindable steel hardness metal, high work efficiency

Grindable steel hardness metal, high work efficiency

› See more product details

New (1) from $9.36 & FREE shipping.

They come in different sizes, lengths and coarseness.

Forrest

--

Forrest

I-20 USA-645

Hernando, Florida

"There's not enough rum in the drum"

--

- Rank: Lubber

- Registered: Jan 08, 2007

- Last visit: Mar 23, 2023

- Posts: 49

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

HI Forrest - thanks for the input

i have round files that are pretty similar to the rat tail ones you show -

as per the dremel ... i am a little hesitant to put a power tool in there ... where i can't see - i am sure it could be done but i am sure i could screw that up too... the walls are really thin in spots and it would be tough to feather any sanding without enlarging the hole (i think)

i am gonna try to sans power tools but thanks for the tip if i need to get some powersanding in there

Edited by MN3 on Jul 17, 2019 - 02:12 PM.

i have round files that are pretty similar to the rat tail ones you show -

as per the dremel ... i am a little hesitant to put a power tool in there ... where i can't see - i am sure it could be done but i am sure i could screw that up too... the walls are really thin in spots and it would be tough to feather any sanding without enlarging the hole (i think)

i am gonna try to sans power tools but thanks for the tip if i need to get some powersanding in there

Edited by MN3 on Jul 17, 2019 - 02:12 PM.

- Rank: Mate

- Registered: Apr 15, 2005

- Last visit: Apr 30, 2025

- Posts: 576

Tip the boat on its side. Not too bad with a second person. Then you will likely be able to get in there with a hand and sandpaper. I could on the Infusion trunk, similar location, this is the Mk. 2 trunk that is very narrow. Scuff the trunk, wet out a piece of 6oz fiberglass, guide into place with sticks as necessary. Let cure and go sailing.

I say all this because the centerboard doesn't contact that location per your description and 6oz cloth is 0.010" thick, so won't change the contact either. Brushing G/Flex in will likely work just as well, but you have more control with 6oz cloth in terms of wet out and you can let tack up before installation.

I did the same thing but used a tube of UV cure epoxy in addition to the fiberglass: https://www.solarez.com/product/solarez-extreme-3-5-oz-tube/

Amazon carries it as well. This was an on the beach repair in the Florida 300 and it held for the next 200 miles so...

I say all this because the centerboard doesn't contact that location per your description and 6oz cloth is 0.010" thick, so won't change the contact either. Brushing G/Flex in will likely work just as well, but you have more control with 6oz cloth in terms of wet out and you can let tack up before installation.

I did the same thing but used a tube of UV cure epoxy in addition to the fiberglass: https://www.solarez.com/product/solarez-extreme-3-5-oz-tube/

Amazon carries it as well. This was an on the beach repair in the Florida 300 and it held for the next 200 miles so...

- Rank: Mate

- Registered: Jun 15, 2016

- Last visit: Apr 14, 2022

- Posts: 181

- Rank: Lubber

- Registered: Jan 08, 2007

- Last visit: Mar 23, 2023

- Posts: 49

Andrew,

Some dremels offer flex cables about 18-20" long This way the sander stays outside and you sand with the cable and just head. Think of a dentist. Check Walmart for them or hobby shop. I had to grind out the glue on carpet in my well to replace the padding Dusty, but works well.

Good luck

Forrest

--

Forrest

I-20 USA-645

Hernando, Florida

"There's not enough rum in the drum"

--

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

- Rank: Mate

- Registered: Apr 15, 2005

- Last visit: Apr 30, 2025

- Posts: 576

Nope, that image shows the tool rigged correctly. It isn't that much smaller than a regular dremel.

I recently saw a Ryobi tool that is very similar, as they made it compatible with their existing lithium drill batteries so had to go to a remote tool head.

Honestly though I think you are overthinking the job...a piece of 80 grit sandpaper is enough to scuff for adhesion of a fiberglass patch.

Edited by samc99us on Jul 18, 2019 - 11:48 AM.

I recently saw a Ryobi tool that is very similar, as they made it compatible with their existing lithium drill batteries so had to go to a remote tool head.

Honestly though I think you are overthinking the job...a piece of 80 grit sandpaper is enough to scuff for adhesion of a fiberglass patch.

Edited by samc99us on Jul 18, 2019 - 11:48 AM.

- Rank: Mate

- Registered: May 08, 2017

- Last visit: Oct 29, 2019

- Posts: 139

I feel for your small clearances. I have a slight leak in a Tennant T9 dagger well... and I can get my hand in there pretty well, since the boards are WAY bigger. The other well is even more entertaining, as there is a jam that no longer allows full insertion of the dagger. Fun.

The better prepared your surfaces are, the better the bond will be. Pre-scuff, and then wipe and irrigate the area with a solvent friendly to whatever adhesive you plan to use (taking care of any foam it may contact)... and leave a fan blowing to clear that solvent.

Use gravity to your best advantage, dunno about the vacuum unless you've got good control over where the epoxy flows when it pulls through. Peelply might help contain the epoxy, but it can't be manipulated/stretched/formed like 'glass... so definitely dry-fit.

Try to patch from outside AND inside, as well... ideally, one within the cure time of the other so that you've basically got an hourglass patch larger on both ends (convoluted as the inside may be).

Post up an update when you're done!

Randii

The better prepared your surfaces are, the better the bond will be. Pre-scuff, and then wipe and irrigate the area with a solvent friendly to whatever adhesive you plan to use (taking care of any foam it may contact)... and leave a fan blowing to clear that solvent.

Use gravity to your best advantage, dunno about the vacuum unless you've got good control over where the epoxy flows when it pulls through. Peelply might help contain the epoxy, but it can't be manipulated/stretched/formed like 'glass... so definitely dry-fit.

Try to patch from outside AND inside, as well... ideally, one within the cure time of the other so that you've basically got an hourglass patch larger on both ends (convoluted as the inside may be).

Post up an update when you're done!

Randii