All boxes are mounted on treated wood that is bolted to the frame with carriage bolts. I did that so that when I get down to florida, and have mast-up storage (God willing), I will be able to easily unscrew the coffin box and store it on the ground under my boat on the beach. I admit, having the tube and the coffin box is probably too much storage but it will give me more storage for moving to florida and then when I get down there I'll just unscrew it and keep it on the beach.

The black box is very helpful for storing life jackets, harnesses, blocks, extra parts, etc. It helps to keep things organized.

This is mostly for traveling. It will help keep my mpg down versus having the bike on the yakima rack on the roof. I ordered the bike fork mount on the internet for $20 shipped and then just used velcro straps to keep the spare tire down. It fits perfectly in the "groove" made by the mast crutch which should help keep it from moving.

I also have my kayak stored under the boat on the trailer for transporting it but I don't have any pictures.

-------------------------------------------------------------------------

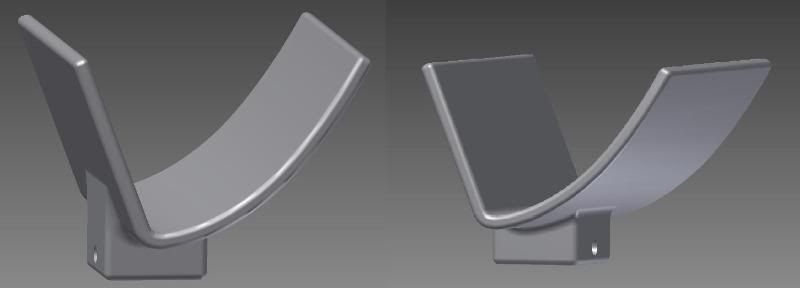

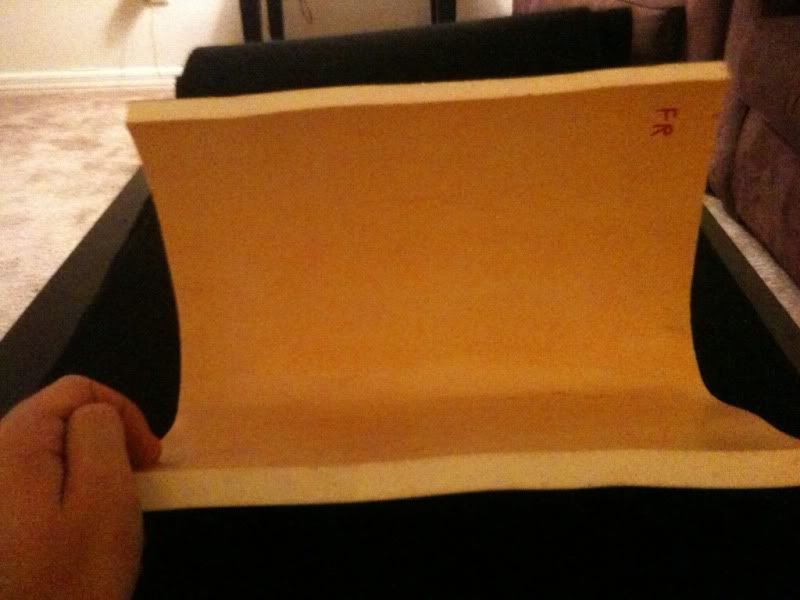

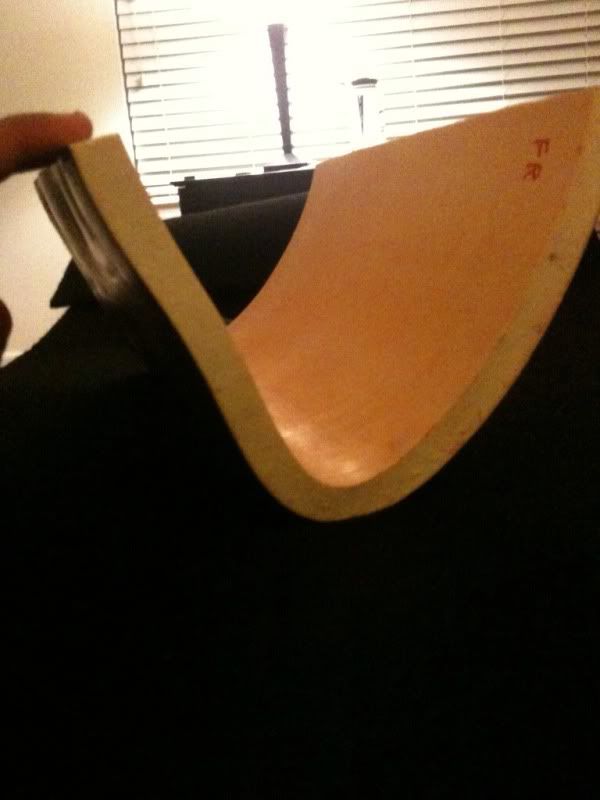

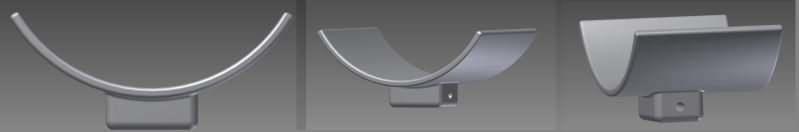

I'm in the process of building custom hull cradles for the trailer. I'll post pictures and maybe a write-up when I'm finished.

Here is a quick preview:

-------------------------------------------------------------------------

Installed the new 12" tires over easter weekend. They are an upgrade from the 8" tires. They should roll over pot-holes better and also spin the hub less.

Fenders were too low so I made some quick brackets to raise them. Now the fenders are kind of small for the bigger tires but I'll make do.

12" tire on the right, 8" on left

-------------------------------------------------------------------------

And then my most recent idea. What about mounting one of these onto the trailer frame to store keys while you're out sailing?:

Master Lock Wall Mount on Amazon

Now you don't have to worry about losing your keys while you're out sailing!

--

-Zach

--