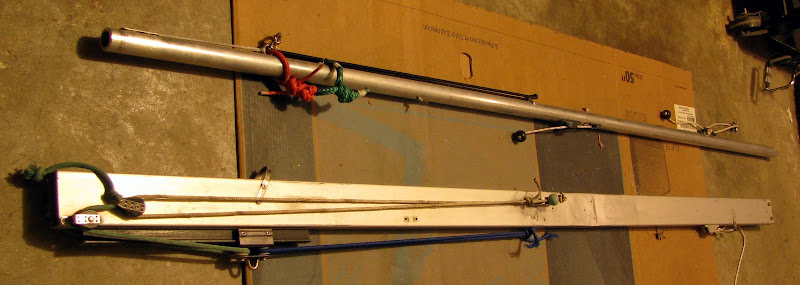

When I got this parted-out cat, the boom was missing, and I went thru the trouble making a copy of the original boom. P18-2s use a square section aluminum tube with a complicated inside outhaul system.

My simplified outhaul system is 2:1, which is not optimal.

Also, I could only get an aluminum tube which has sharp edges instead of a slight radius.

Two things: I chamfered the edge slightly, but the stress from the outhaul car pulling upward when under sail finally caused one edge to crack. it still holds up, but it will have to be repaired.

Also, someone pointed out that square booms are quite a bit more dangerous than round ones when they hit you on the head, which they all eventually will.

I'd prefer to make a round boom this time (I cannot import a second hand one here at reasonable cost). It is possible to get a round aluminum tube.

Does anyone have any suggestions for the outhaul system? Pics, measurements perhaps?

Thanks,

Dan

edited by: catdan, Apr 25, 2010 - 04:50 AM

New boom for a Prindle 18-2

- Rank: Lubber

- Registered: Jul 25, 2008

- Last visit: Aug 10, 2010

- Posts: 91

- Rank: Mate

- Registered: Aug 22, 2007

- Last visit: Jan 07, 2015

- Posts: 742

- Rank: Lubber

- Registered: Jul 25, 2008

- Last visit: Aug 10, 2010

- Posts: 91

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

- Rank: Mate

- Registered: Aug 22, 2007

- Last visit: Jan 07, 2015

- Posts: 742

I like that style as well, however, with a 5.2 (and most older cats I assume) the main isn't high enough aspect to attach the blocks directly to it, specifically the foot is too long. The boom essentially is used for outhaul and mast rotation in that set up, but it seemed like with the longer foot the 7:1 on the blocks would be working against the 2:1 clamcleat on the rotator limiter...which wouldn't end well.

I haven't tried mine yet (project from this winter) but I'm almost certain that the 065 wall isn't enough metal. Since the blocks are attached to the boom and not the sail, the tube needs some rigidity, and it's just too flexible. Remaking it with 125 will cost about $22 and take 3 or 4 hours, so not a big deal, and it will still come in at 2/3rd the weight of the original...I just want to test the current one in light air before starting over.

--

Rob

OKC

Pile of Nacra parts..

--

I haven't tried mine yet (project from this winter) but I'm almost certain that the 065 wall isn't enough metal. Since the blocks are attached to the boom and not the sail, the tube needs some rigidity, and it's just too flexible. Remaking it with 125 will cost about $22 and take 3 or 4 hours, so not a big deal, and it will still come in at 2/3rd the weight of the original...I just want to test the current one in light air before starting over.

--

Rob

OKC

Pile of Nacra parts..

--

- Rank: Mate

- Registered: Aug 22, 2007

- Last visit: Jan 07, 2015

- Posts: 742

- Rank: Administrator

- Registered: Jul 19, 2001

- Last visit: Sep 07, 2025

- Posts: 3460

It seems that all the modern boats use some form of that approach, where the main blocks pull directly on the main sail and not on the boom at all.

I looked at building a new lighter boom for my Hobie 18 using these updated principles but found that the new boats main clew was positioned directly above the main traveler track so the pull from the main blocks was straight down.

But on a Hobie 18 the foot of the main extends well behind the boat, so the blocks must pull on the boom, requiring a very beefy boom.

It's genius really, where sailboats have pretty much always connected the main blocks to the boom, connecting directly to the clew means you can use a tiny boom saving weight and maybe a sailors head.

Added:

I should learn to read the whole thread before typing, since I just repeated a lot of what Rob said!

--

Damon Linkous

1992 Hobie 18

Memphis, TN

Join the discussion at the all new TheBeachcats.com Forums HERE.

https://thebeachcats.temp…l.host/forums/site-talk/

--

- Rank: Chief

- Registered: Jun 24, 2009

- Last visit: Jun 15, 2023

- Posts: 1555

Hey Rob,

I was looking at doing something similar to my 5.2. What do you think about using an old sailboard mast for a boom? I have a couple of these kicking around, they aren't the super thin light ones they use these days, but mid 80's carbon fiber overbuilt ones. It would reduce some weight and make less of a dent in my head if it made contact.

Do you have some closeups of the outhaul system you put together? How did you get 4:1 internally? i.e. what type of blocks did you use inside? That is definitely a project I would like to try out myself!!

--

Dave Bonin

1981 Nacra 5.2 "Lucile"

1986 Nacra 5.7 "Belle"

Winnipeg, Manitoba, Canada

--

I was looking at doing something similar to my 5.2. What do you think about using an old sailboard mast for a boom? I have a couple of these kicking around, they aren't the super thin light ones they use these days, but mid 80's carbon fiber overbuilt ones. It would reduce some weight and make less of a dent in my head if it made contact.

Do you have some closeups of the outhaul system you put together? How did you get 4:1 internally? i.e. what type of blocks did you use inside? That is definitely a project I would like to try out myself!!

--

Dave Bonin

1981 Nacra 5.2 "Lucile"

1986 Nacra 5.7 "Belle"

Winnipeg, Manitoba, Canada

--

- Rank: Mate

- Registered: Aug 22, 2007

- Last visit: Jan 07, 2015

- Posts: 742

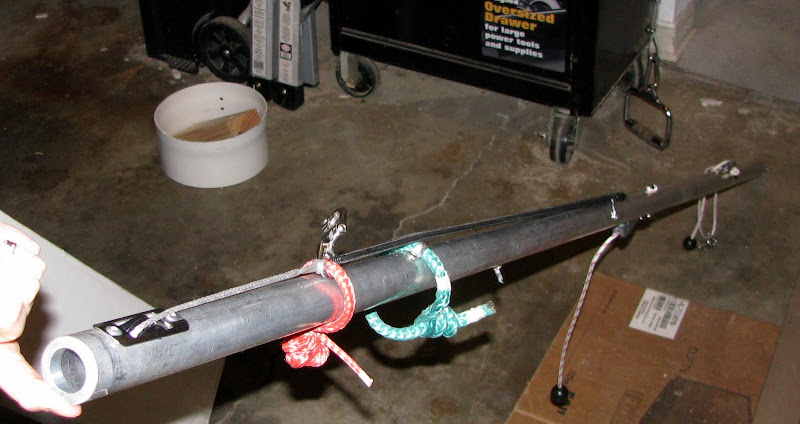

I spliced two dyneema lines to the ronstan 20mms, with one luggage tagged to the snap shackle for the outhaul. Those two cascade, with a 3/16 sta-set line running through the last one and out through a thru-deck to the cleat. I can't really take a picture b/c its inside the tube. The outhaul actually runs very smoothly. I was a bit concerned about the soft shackles sliding well under load, but that doesn't so far seem to be the case.

I have a notepad with the drawing I used to make it laying around somewhere...unfortunately I have more projects than sense and all the stacks of notes I CAN find don't seem to be related to this project.

The trickiest part is probably the thru-deck in the center, since it has to go in after the two blocks with a line running through it. The 1.5" tube leaves zero extra room to work with lines around the blocks. It all has to slide in in place.

The thru decks fasten to the INSIDE not the outside, so they are a little tougher than they look at first glance, but a little patience and LOTS of string got it done.

I also takes a little planning to make sure that the paths traveled by the blocks don't interfere with the backs of the blind rivets...I mostly got lucky in this regard.

The thick ring at the back of the boom looks nice, but it was a total accident and made it a bit tougher to manipulate the rear thru-deck block. I was trying to test fit my fittings (had a few chunks of aluminum machined, was an excellent idea) and accidentally press-fit one. About 15 minutes of sawing later and I had a smooth little ring on the inside, and a shorter fitting.

--

Rob

OKC

Pile of Nacra parts..

--

I have a notepad with the drawing I used to make it laying around somewhere...unfortunately I have more projects than sense and all the stacks of notes I CAN find don't seem to be related to this project.

The trickiest part is probably the thru-deck in the center, since it has to go in after the two blocks with a line running through it. The 1.5" tube leaves zero extra room to work with lines around the blocks. It all has to slide in in place.

The thru decks fasten to the INSIDE not the outside, so they are a little tougher than they look at first glance, but a little patience and LOTS of string got it done.

I also takes a little planning to make sure that the paths traveled by the blocks don't interfere with the backs of the blind rivets...I mostly got lucky in this regard.

The thick ring at the back of the boom looks nice, but it was a total accident and made it a bit tougher to manipulate the rear thru-deck block. I was trying to test fit my fittings (had a few chunks of aluminum machined, was an excellent idea) and accidentally press-fit one. About 15 minutes of sawing later and I had a smooth little ring on the inside, and a shorter fitting.

--

Rob

OKC

Pile of Nacra parts..

--

- Rank: Mate

- Registered: Aug 22, 2007

- Last visit: Jan 07, 2015

- Posts: 742

- Rank: Mate

- Registered: Aug 22, 2007

- Last visit: Jan 07, 2015

- Posts: 742

- Rank: Mate

- Registered: Aug 22, 2007

- Last visit: Jan 07, 2015

- Posts: 742

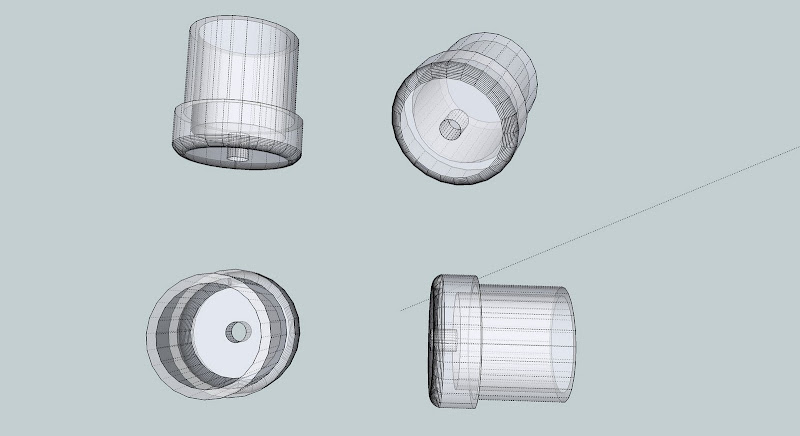

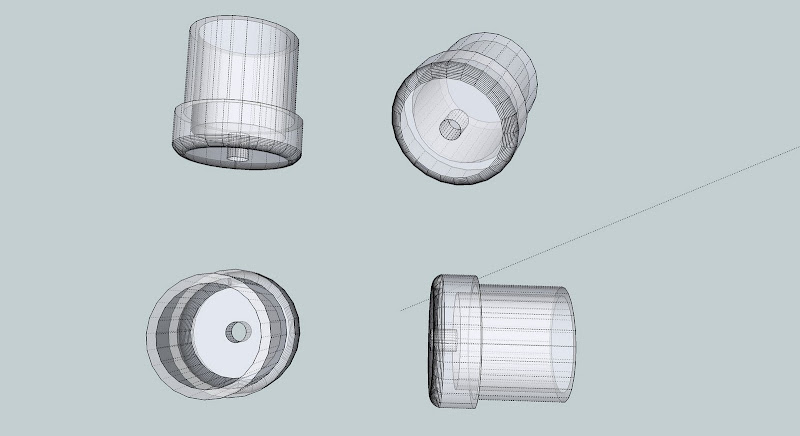

Here's the machined cap:

The shop that did them for me charges $45/hour or something like that, but this was a small enough job that I don't think it cost anything, but the dimensions came out a touch off, too...still got more than I paid for. I had to chuck the one I used in my drill press and wrap the belt from my belt sander around it. Took about 10 minutes of sanding to get what I wanted off of it. You can see the other one I sanded down and tried to test fit. Oops.

--

Rob

OKC

Pile of Nacra parts..

--

The shop that did them for me charges $45/hour or something like that, but this was a small enough job that I don't think it cost anything, but the dimensions came out a touch off, too...still got more than I paid for. I had to chuck the one I used in my drill press and wrap the belt from my belt sander around it. Took about 10 minutes of sanding to get what I wanted off of it. You can see the other one I sanded down and tried to test fit. Oops.

--

Rob

OKC

Pile of Nacra parts..

--

- Rank: Lubber

- Registered: Jul 25, 2008

- Last visit: Aug 10, 2010

- Posts: 91

- Rank: Mate

- Registered: Feb 19, 2008

- Last visit: Aug 26, 2023

- Posts: 671

making 1 out of polyester frb means you might as well use an old windsurfer mast

i too have been thinking of lightening my 5.2 somehow and the boom is 1 of the easiest areas to trackle

though i also wanted a bit of carbon bling visible by using an old carbon fiber windsurfer mast. have a bit of 1 ogf those acting as my tramp tube at the moment

another good saving would be swapping out the rudders and daggers for the almost identically sized but half the weight, weta tri dagger and rudders

but pricey

stood on the scales the other day just before putting up the 5.2's mast. fully rigged with diamonds, stays, halyards, trap wires etc. it was just under 30kg, wish i could get an old mastrom carbon tornado mast from somewhere, then we'd be talking easier righting

since the farrier f22 is going to use synthetic stays maybe i should look at them and/or swap out the heavy jib tramp wires for synth

edited by: erice, Apr 30, 2010 - 08:46 PM

i too have been thinking of lightening my 5.2 somehow and the boom is 1 of the easiest areas to trackle

though i also wanted a bit of carbon bling visible by using an old carbon fiber windsurfer mast. have a bit of 1 ogf those acting as my tramp tube at the moment

another good saving would be swapping out the rudders and daggers for the almost identically sized but half the weight, weta tri dagger and rudders

but pricey

stood on the scales the other day just before putting up the 5.2's mast. fully rigged with diamonds, stays, halyards, trap wires etc. it was just under 30kg, wish i could get an old mastrom carbon tornado mast from somewhere, then we'd be talking easier righting

since the farrier f22 is going to use synthetic stays maybe i should look at them and/or swap out the heavy jib tramp wires for synth

edited by: erice, Apr 30, 2010 - 08:46 PM

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

you mean the cheese cutter for the 4 way system?

if so i went to vectran, and others i know use dyneema. i went to vectran to reduce creep but i saw that Tornado (from the other forum) leaves a great amount of slack in his to reduce the pull on the tracks (mine are pulling out)

ps my reason for the change was not to save weight but to keep more skin on my legs

- Rank: Chief

- Registered: Jun 24, 2009

- Last visit: Jun 15, 2023

- Posts: 1555

I hear ya, I worked out the weight savings for going from steel to synthetic rigging. It wasn't enough to make it worth it. Carbon boom and mast are probably the simplest changes and provide biggest bang. Still not cheap though. Quite a few 5.5 owners switched to a carbon mast a few years ago, I think they must have done a group purchase to reduce costs, otherwise it would have been astronomically expensive.

I am more wanting a round lower aspect boom to get some extra headspace when tacking and to soften the blow if I get hit with the thing. With me and my crew weighing over 400 lbs, there are definitely cheaper ways to lighten the boat (like tossing the crew overboard at an opportune moment or eating less cheeseburgers).

D.

--

Dave Bonin

1981 Nacra 5.2 "Lucile"

1986 Nacra 5.7 "Belle"

Winnipeg, Manitoba, Canada

--

I am more wanting a round lower aspect boom to get some extra headspace when tacking and to soften the blow if I get hit with the thing. With me and my crew weighing over 400 lbs, there are definitely cheaper ways to lighten the boat (like tossing the crew overboard at an opportune moment or eating less cheeseburgers).

D.

--

Dave Bonin

1981 Nacra 5.2 "Lucile"

1986 Nacra 5.7 "Belle"

Winnipeg, Manitoba, Canada

--

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

That is ridiculous ... NEVER reduce your cheeseburgers... you never know when you may be stranded (like if the wind stops for 10 minutes) and will need those calories :)

Even with group rates, its still several grand for a carbon mast. my friend works at a spar shop and he has tried to get best possible rates for a bulk purchase and its still 3x the cost of an aluminum one.

Even with group rates, its still several grand for a carbon mast. my friend works at a spar shop and he has tried to get best possible rates for a bulk purchase and its still 3x the cost of an aluminum one.

- Rank: Chief

- Registered: Jun 24, 2009

- Last visit: Jun 15, 2023

- Posts: 1555

Hey check out the new wildcat outhaul!

http://www.thebeachcats.com/index.php?module=pictures&g2_itemId=73363

That is something that I could do on my cat without having to fiddle with internally routing the blocks. Next off to find a piece of thick walled aluminum tubing...

--

Dave Bonin

1981 Nacra 5.2 "Lucile"

1986 Nacra 5.7 "Belle"

Winnipeg, Manitoba, Canada

--

http://www.thebeachcats.com/index.php?module=pictures&g2_itemId=73363

That is something that I could do on my cat without having to fiddle with internally routing the blocks. Next off to find a piece of thick walled aluminum tubing...

--

Dave Bonin

1981 Nacra 5.2 "Lucile"

1986 Nacra 5.7 "Belle"

Winnipeg, Manitoba, Canada

--

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

- Rank: Chief

- Registered: Jun 24, 2009

- Last visit: Jun 15, 2023

- Posts: 1555

Hey guys, I think I'm going to try and make a round boom with an exteranl outhaul for my 5.2. On Murray's web site you can get aluminum end caps for a 1.5" spin pole that fit a tube with a 3/16" wall thickness (half way between 0.063" and .125). Do you think this will be strong enough for a boom? Anyone have a source for end cap fittings (other than a local machinist)for larger tubes?

D.

--

Dave Bonin

1981 Nacra 5.2 "Lucile"

1986 Nacra 5.7 "Belle"

Winnipeg, Manitoba, Canada

--

D.

--

Dave Bonin

1981 Nacra 5.2 "Lucile"

1986 Nacra 5.7 "Belle"

Winnipeg, Manitoba, Canada

--

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

i think a standard spin pole (no idea what the I/D or O/D is) could work.

why do you need endcaps? unless you plan on backing the boat up very fast.. i don't know how you could do any damage with the aft part and the forward part will be "looking" at your mast...

that being said, if you really want them i think apsltd.com sells them ( APS Part Number: SLD53485301 - Price: $54.00) but i would go to a hardware store and look for pvc or simmilar.

why do you need endcaps? unless you plan on backing the boat up very fast.. i don't know how you could do any damage with the aft part and the forward part will be "looking" at your mast...

that being said, if you really want them i think apsltd.com sells them ( APS Part Number: SLD53485301 - Price: $54.00) but i would go to a hardware store and look for pvc or simmilar.

- Rank: Chief

- Registered: Jun 24, 2009

- Last visit: Jun 15, 2023

- Posts: 1555

The end caps would just be to prevent crushing at the end where you attach the goose neck to (same reason they are used on a spin pole). The one at Murrays is similar to the one Yurdle showed above, but they are only $10.

D.

--

Dave Bonin

1981 Nacra 5.2 "Lucile"

1986 Nacra 5.7 "Belle"

Winnipeg, Manitoba, Canada

--

D.

--

Dave Bonin

1981 Nacra 5.2 "Lucile"

1986 Nacra 5.7 "Belle"

Winnipeg, Manitoba, Canada

--

- Rank: Mate

- Registered: Aug 22, 2007

- Last visit: Jan 07, 2015

- Posts: 742

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

actually, on a spin pole they have a few uses but i have never heard of crushing being a reason why.

1. end caps are often used for internal tack lines, they come out the end and up to the block. Delron works will dyneema and alum for any line. SNU sells an alum one

2. to avoid "cookie-cutting" of any object you run into (another boat, person, etc) a "cover" is required in the F16 rules i believe for this exact reason

1. end caps are often used for internal tack lines, they come out the end and up to the block. Delron works will dyneema and alum for any line. SNU sells an alum one

2. to avoid "cookie-cutting" of any object you run into (another boat, person, etc) a "cover" is required in the F16 rules i believe for this exact reason

- Rank: Chief

- Registered: Jun 24, 2009

- Last visit: Jun 15, 2023

- Posts: 1555

- Rank: Chief

- Registered: Jun 24, 2009

- Last visit: Jun 15, 2023

- Posts: 1555

I just acquired 2 - 10 foot lengths of 1.5" diameter 6061 Aluminum tube with a 3/32" wall thickness. Do you think this will hold up to the forces put on a 5.2 boom?

Does anyone have a round boom and if so what are the dimensions? Rob what diameter was the tubing you used? Catdan, do you have specs on teh tubine you used

If I attach the main sheet directly to the main clew (like more modern boats) do you think it will rip out the 3:1 outhaul? It would move the main sheet about 8" back and the high angle is concerning..

edited by: Wolfman, May 28, 2010 - 11:59 PM

--

Dave Bonin

1981 Nacra 5.2 "Lucile"

1986 Nacra 5.7 "Belle"

Winnipeg, Manitoba, Canada

--

Does anyone have a round boom and if so what are the dimensions? Rob what diameter was the tubing you used? Catdan, do you have specs on teh tubine you used

If I attach the main sheet directly to the main clew (like more modern boats) do you think it will rip out the 3:1 outhaul? It would move the main sheet about 8" back and the high angle is concerning..

edited by: Wolfman, May 28, 2010 - 11:59 PM

--

Dave Bonin

1981 Nacra 5.2 "Lucile"

1986 Nacra 5.7 "Belle"

Winnipeg, Manitoba, Canada

--

- Rank: Mate

- Registered: Aug 22, 2007

- Last visit: Jan 07, 2015

- Posts: 742

Even if you rotated the rear beam back some to keep from tearing up the traveler, I think the load from the main blocks would tear up the mast rotator limiter or the outhaul or both. You need a main with a shorter foot to set it up that way.

I just bought another tube in case my first one is too thin, but I could only find 1/8 as the next step up from 1/16. I'd much rather try 3/32, as 1/8 seems like too much metal. I'll have a much better idea once I actually try the one I built, though.

--

Rob

OKC

Pile of Nacra parts..

--

I just bought another tube in case my first one is too thin, but I could only find 1/8 as the next step up from 1/16. I'd much rather try 3/32, as 1/8 seems like too much metal. I'll have a much better idea once I actually try the one I built, though.

--

Rob

OKC

Pile of Nacra parts..

--

- Rank: Chief

- Registered: Jun 24, 2009

- Last visit: Jun 15, 2023

- Posts: 1555

What diameter of pipe did you get? I'm thinking of getting a 1/8" thickness 2" diameter pipe instead of using the 1.5" 3/32" diameter pipe.

Wish I new more about the magnitude of loads that could be experienced, it would make figuring out the required boom strength much easier.

--

Dave Bonin

1981 Nacra 5.2 "Lucile"

1986 Nacra 5.7 "Belle"

Winnipeg, Manitoba, Canada

--

Wish I new more about the magnitude of loads that could be experienced, it would make figuring out the required boom strength much easier.

--

Dave Bonin

1981 Nacra 5.2 "Lucile"

1986 Nacra 5.7 "Belle"

Winnipeg, Manitoba, Canada

--

- Rank: Mate

- Registered: Aug 22, 2007

- Last visit: Jan 07, 2015

- Posts: 742

I built the first one out of 1.5" OD, 1/16" wall, 6061. I used it today.

It flexes like crazy. I won't take it out 2-up, but 1-up it seems OK. I need to talk to someone that knows aluminum better than I, though, before I count on this one as 'safe'.

When flying a hull and trapped out, if you were to draw a line between the top of the front and back of the boom, I bet the top of the center of it is about 3" below the line. I don't know how much the aluminum can flex before giving out, but I'd imagine that it's nearing its limit. (at r=.5d, (1/24)d thickness, 64d length, and 2d distance of flex in the center...I think that's the relevant info for any of you engineers)

I also have a 1.5", 125 wall thickness tube, and a 2"OD, 065 wall thickness tube, both of which are FAR stiffer. If the blocks will fit on the inside of the 1.5"/125 tube I'll probably switch to that if this one breaks or if I get too concerned about safety.

--

Rob

OKC

Pile of Nacra parts..

--

It flexes like crazy. I won't take it out 2-up, but 1-up it seems OK. I need to talk to someone that knows aluminum better than I, though, before I count on this one as 'safe'.

When flying a hull and trapped out, if you were to draw a line between the top of the front and back of the boom, I bet the top of the center of it is about 3" below the line. I don't know how much the aluminum can flex before giving out, but I'd imagine that it's nearing its limit. (at r=.5d, (1/24)d thickness, 64d length, and 2d distance of flex in the center...I think that's the relevant info for any of you engineers)

I also have a 1.5", 125 wall thickness tube, and a 2"OD, 065 wall thickness tube, both of which are FAR stiffer. If the blocks will fit on the inside of the 1.5"/125 tube I'll probably switch to that if this one breaks or if I get too concerned about safety.

--

Rob

OKC

Pile of Nacra parts..

--