|

Rudder Stiffening Flexy Rudders? Add Unidirectional Carbon Fibers By Gary Friesen |

|

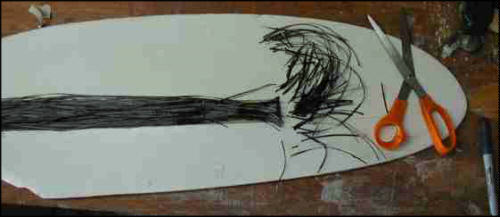

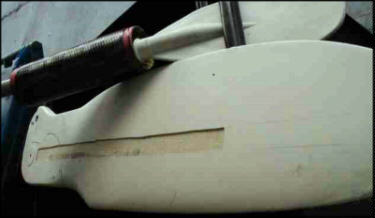

Adding in some extra exoskeletal structural members (external stringers) for rudder

stiffening.

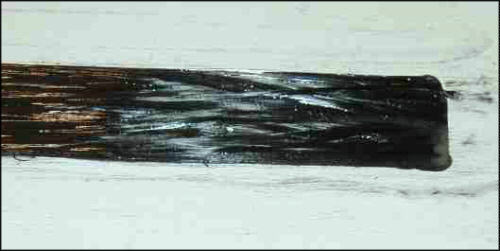

I've been working on a rudder assembly modification for my cat. The rudders that I have been experimenting with have been working pretty well for me but they have a little bit more flex in them than I would like them to have. I decided to stiffen them using some carbon fiber "tow." Tow is a strand of hundreds or thousands of carbon fibers which run all in same direction. Many strands of tow can produce a pony tail like wad of fibers which can be formed into various shapes such as square or round. I decided to introduce two sub surface stringers along the chord of the rudders. I started by using a router with a high carbon steel bit to dig out a groove in each side of the rudder. The groove is about 1 1/4" wide and a little less than 1/8" deep. It runs most of the length of the blade and is in line with the pivot bolt hole and the tip of the blade. |

| The depth of the groove is enough to get beyond the gelcoat and into the glass, without go so far as to remove all the original glass. This will allow my epoxy, tow composite to get a good grip on the existing external structure of the rudder. It should allow me to later reform and cover the surface using gelcoat. |